Basic principle

By means of 3D silicone plotting a variety of silicone structures can be created - without any molds or tools. The CNC-controlled process provides a standardized production method, as well for complex products. We constantly develop new products, materials and processes at our laboratory unit. Higher quantities for the medical technology sector are produced on a powerful series system.

Plotting technology for production of three-dimensional silicone products

3D silicone plotting is an additive production process and differs from standard generative technologies. The final products are elastic bodies. Nearly all fluid silicones can be processed. These liquid materials are applied thread-like in layers on a base surface. The advantage of the CNC-controlled process is that it permits a high reproducibility and flexible adaptations for the fabrication of the required product. In the fields of wound care we combine the numerous advantages of the material and our innovative production technology to create European-wide unique silicone wound dressings .

Consistent material feeding by precise dosing system

Our plotting technology is a so-called extrusion forming process which is constantly developed and optimized. This process enables a computer-controlled material discharge of liquid silicone. The material is stored in reservoirs and is applied by means of nozzles.

The ductile thread of raw material is deposited on a structure carrier unit according to a pre-defined process of movements through a NC program. Its diameter can be adjusted as per product requirements. Due to the adjustable material dosing unit, high-viscous liquid silicones can be processed as well.

High efficiency with 3D silicone plotting

Producing silicone bodies via a computer-controlled plotting technology is an economical process. Compared to injection molding, no time-consuming production or purchasing of mold tools is required.

Prototypes and individual parts can be generated within only few days. With 3D silicone plotting the required high-quality product can be fabricated on a fast and cost-effective basis.

Do you need further information? Please do not hesitate to contact us.

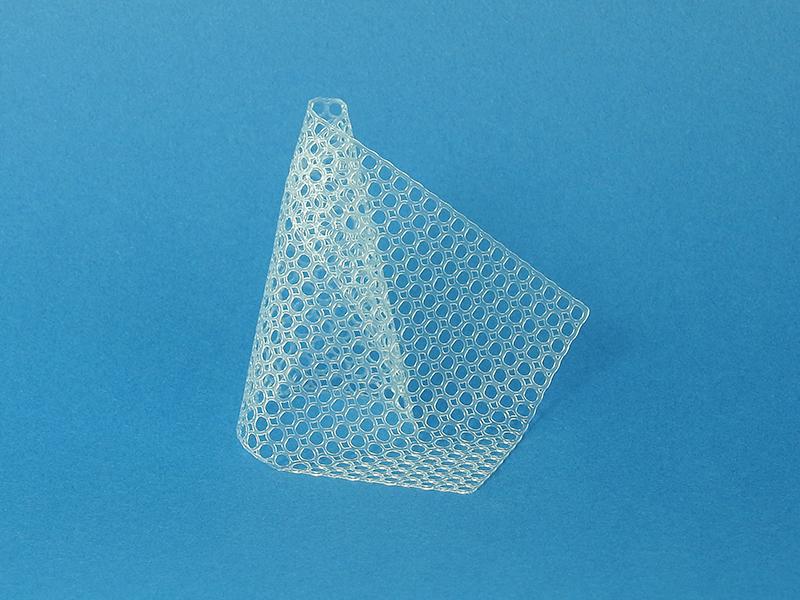

Two samples demonstrating the variety of 3D silicone products – cylindrical-shaped grid and very fine scaffold

Numerous options with 3D silicone – surface coating on a transparent silicone mold

Laboratory unit

Pure innovation - developing silicone structures at our laboratory unit

You need a silicone object with special properties? As an expert for silicone production we develop the object you request according to your special requirements and ideas. Our experts use proven materials or create and test new silicones for you at first at our laboratory unit, because each silicone material behaves differently and each application area requires special adaptations in the production process.

Test runs for new 3D silicone moldings

To guarantee a reliable high-quality standard of your silicone product, we first define the relevant process windows for prototypes and samples by means of our laboratory equipment.

The laboratory plotter provides a construction space of 522 x 337 x 310 mm to produce 3D silicone parts.

As a reliable partner we use our know-how for a cost-efficient development of precise components made of silicone rubber. Contact us! We are looking forward to your request.

Created on the KET laboratory facility – multi-layer grid, applicable as a damping element

Any pore design is possible - grids with rhombic and circular perforations

Series system

Silicone products in series - You set the quantity

The KET series plotting system is an advanced version of our laboratory plant and has been designed especially for the production of medical wound dressings. These serve as a primary layer in modern wound care.

Our high-quality silicone dressings are well tolerated by the human body and do not cause any defensive reaction. The series plotter processes exclusively medically approved LSR (liquid silicone rubber). Objects are produced under clean-room conditions (class 8, ISO 14644)

The plant has a maximum construction space of 500 x 500 x 15 mm. This means that depending on the product, up to 10,000 m² of structured surfaces can be realized per year.

You have some questions on your product options? Please, contact our experts for advice.