The extensive range of different materials and flexible processing procedures provide unlimited application possibilities for our products.

Our current focus:

- Wound dressings made of pure silicone for the medical technology sector

- Scaffolds / cell carrier for the biotechnological sector

- complex fabrics for filter technology

- demanding geometries in the field of sealing technology

As an innovative partner we have gained unique know-how of 3D silicone plotting. Our experts realize your specific silicone product in close cooperation with you - economically, on time and with a high awareness of quality. Please, see the following information on proven products from our production.

Medical technology sector

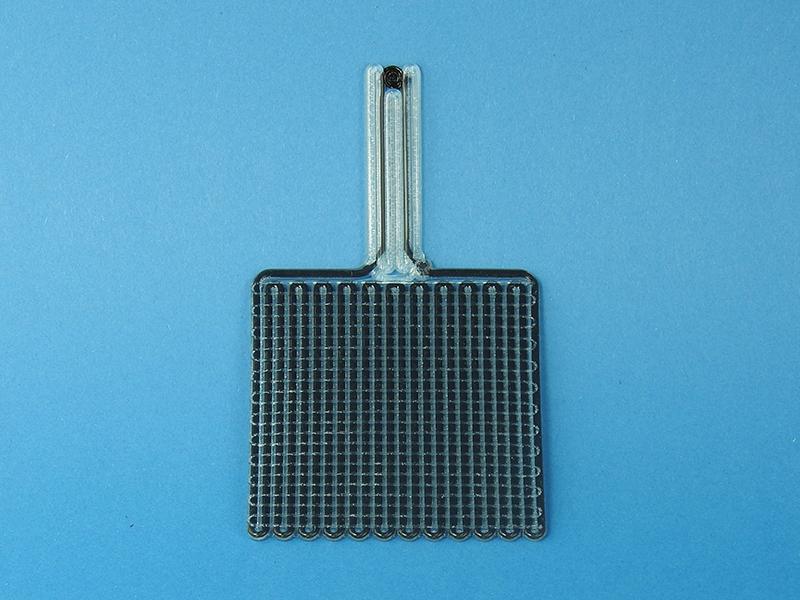

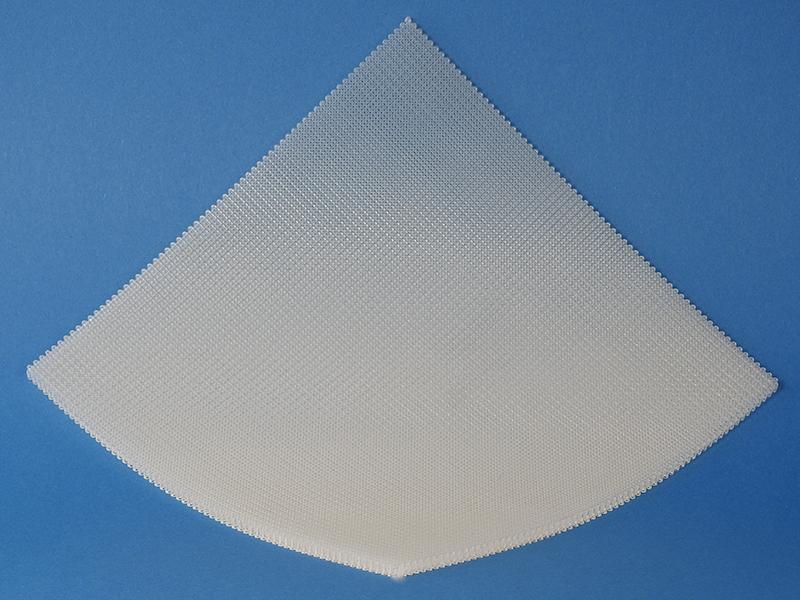

Wound care dressing made of silicone

Our primary wound care dressings are made pure silicone. We combine the perfect material properties of a medically certified silicone with our innovative production processes. The advantages of a patented KET silicone wound dressing by KET:

- The dressings are exclusively made of silicone. Textiles which could grow together with the wound are not used.

- The material is water-repellent.

- The geometrical structure of the grid surface permits the optimum moisture level. Excessive wound fluid can drain to the outside.

- Due to atraumatic edges (no uncoated threads on manually cut edges) the product has proven to be very gentle on skin.

- The wound contact pad is elastic and flexibly adapts to uneven wounds. Therefore the patients enjoy a high level of mobility.

- Size, shape and color of the wound care dressings can be adapted upon request.

- The manufacturer certificate guarantees the bio-compatibility of the silicone.

Biocompatible wound dressings – in different sizes

2K electrode used in the medical technology– black strip conductor coated with a transparent isolation

Sample of a membrane stabilized by a silicone grid

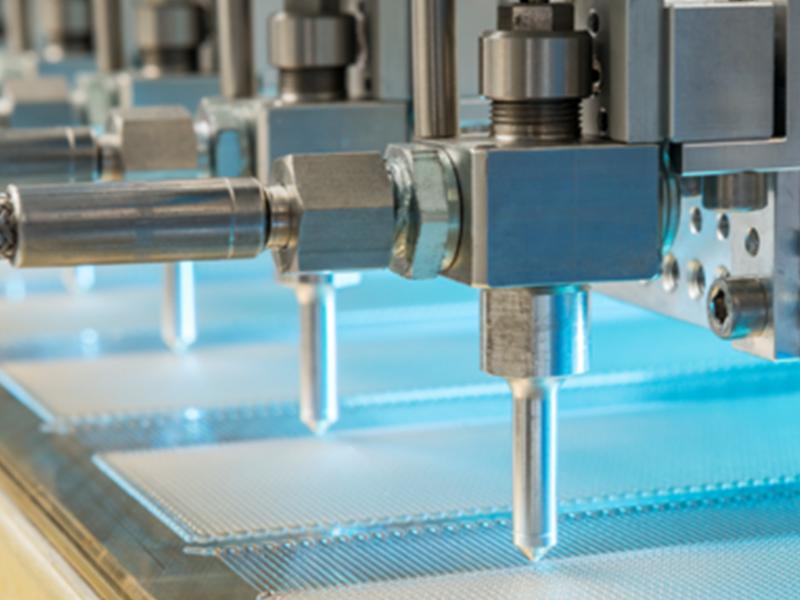

First visual check of 3D silicone wound dressings – The strict quality control chain begins right there.

3D silicone grids in serial production

Biotechnology

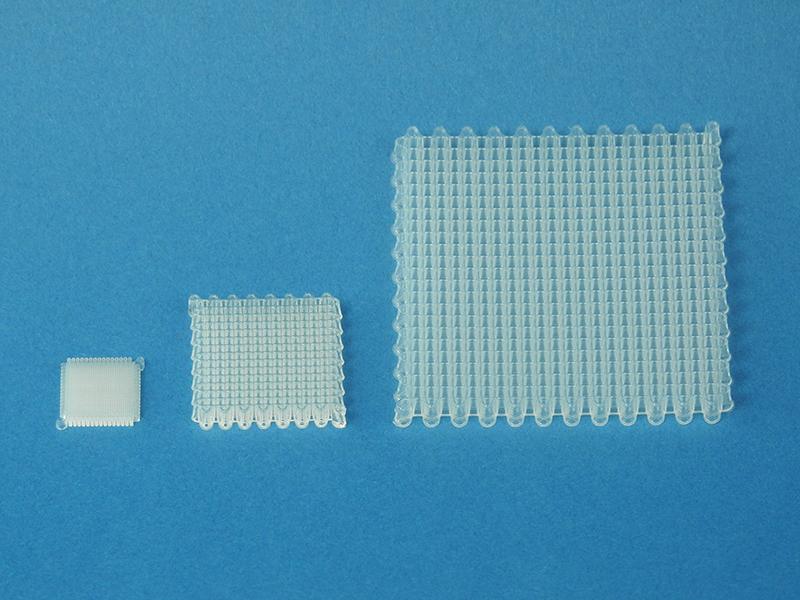

Scaffolds - three-dimensional cell culture carrier

In the field of bio-technology silicone scaffolds serve as cell carriers or frame for cell structures. These carrier forms are used in cell cultivation and research. Equipped with a nutrient medium, our scaffolds offer the perfect growing environment to the cells as the special carrier surfaces are closer to their natural environment than two-dimensional structures.

A current research project of the medical faculty at the Leipzig University is currently dealing with the positive effect of our 3D silicone scaffolds regarding the colonization and differentiation of human stem cells. The application of silicone scaffolds, for example, enables non-animal tolerance tests of medications.

Flexible adaptation of silicone structure

The 3D plotting technology offers perfect requirements for various application areas. The program-based structure generation enables to adapt size and shape of the scaffolds to individual customer requirements. As per request and need our experts modify thread size, pore and matrix structure. The KET silicone scaffolds can therefore be adapted to various kinds of cultivation systems (e.g. structure size, cell types).

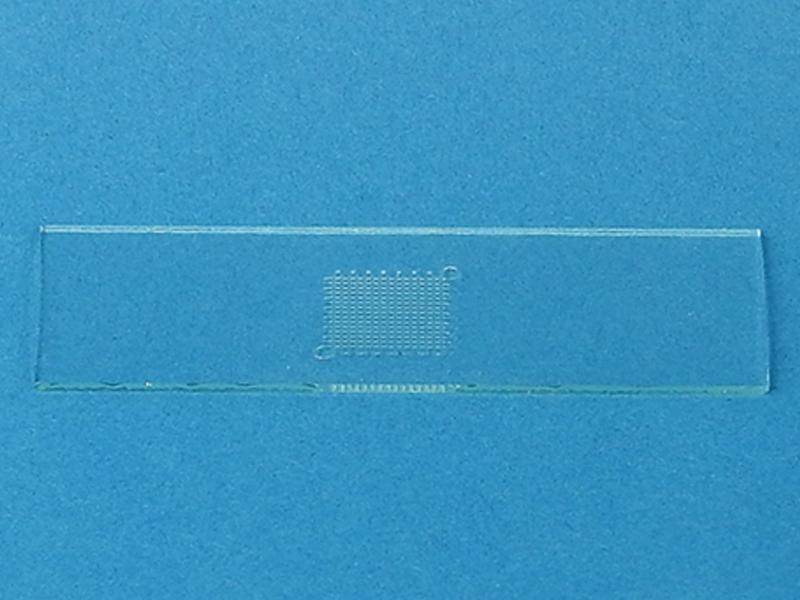

One-layer silicone grid on a glass microscope slide

Scaffolds made of biocompatible silicone for the biotechnological sector – different sizes of pores (left: 0.2 mm, right: 2 mm) and thread thicknesses (left: 0.2 mm, right: 0.5 mm)

Filter technology

Silicone filter elements for individual requirements

The application areas for modern filter technology are constantly developing. Due to a special processing technology for liquid silicones, we are able to meet the highest requirements for filter elements. With our 3D production processes our experts generate your requested product.

Proven filter performance

Regarding heavy metal filtering the effective power of our combined 3D silicone components has already been confirmed. An increase in precipitation through filter elements can be proven by adding biopolymers. Based on this technology different degrees of complexity can be realized in the generation process. A high media flow and a high filtering performance at the same time are guaranteed.

Multi-layer 3D silicone grid – suitable as filter element or mat for the filter technology sector

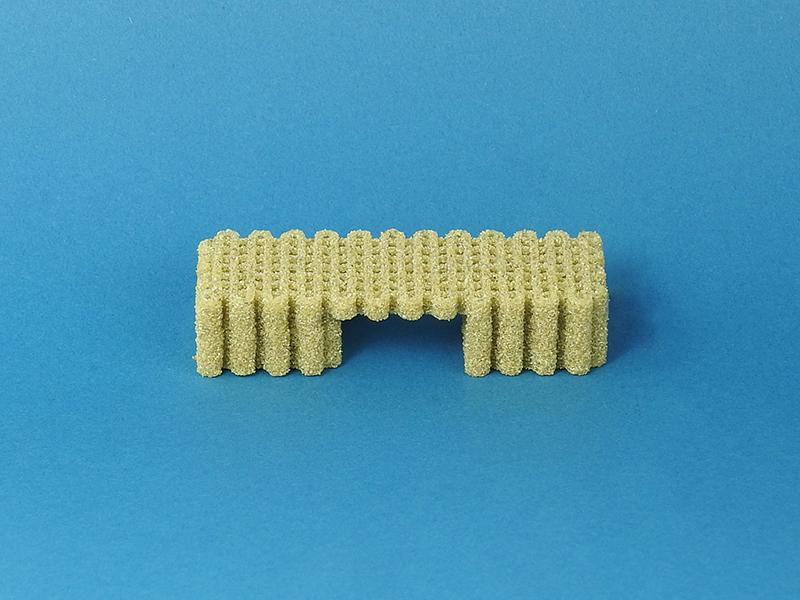

Flocked 3D silicone product for the filter technology sector – also overhangs can be realized

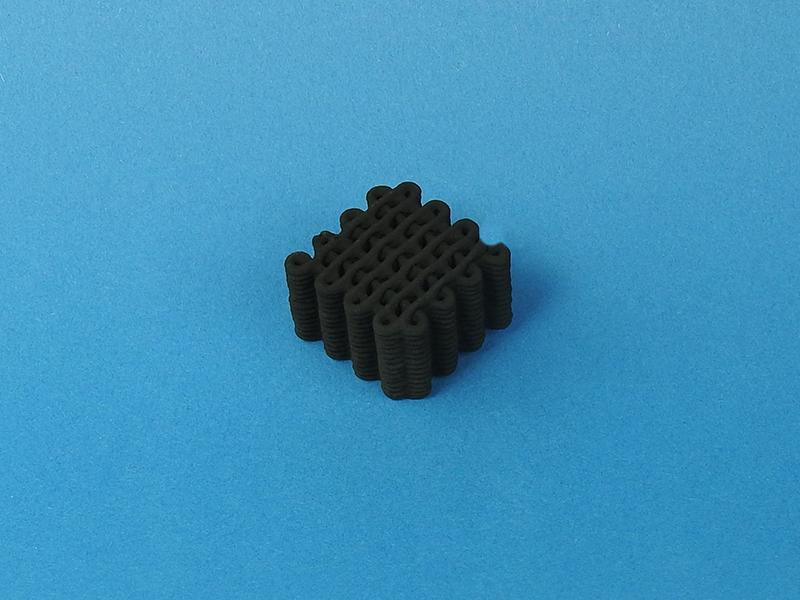

3 D silicone filter element - with active carboncoating

Sealing technology

Range of application for various industrial sectors

The 3D plotting technology is also suitable for a precisely contoured application of a silicone thread on different surfaces and bodies. Sealing elements can therefore be integrated in highly sophisticated geometries. A cost-intensive usage of tools is not necessary. Due to our program-controlled processing method the geometries can be optimized rapidly. Our seals and sealing elements made of silicone, for example, are used in the field of special mechanical engineering on a regular basis.

Individually adapted sealing type, applied to a polypropylene film