The silicone material

We process liquid silicones and will also find the perfect material for your application area. For applications in the medical technology and in the biotechnological sector we use a wide range of biocompatible silicones that have been tested and approved by the manufacturer, for example according to USP class VI and ISO 10993.

Not all types of silicone are the same

The material silicone is perfectly suitable for various application areas. It has, for example, a high flexibility and elasticity, and is highly heat-resistant, colorless, transparent and non-odorous. Only liquid silicones are used for 3D plotting.

We divide into the following material groups:

- The two-component liquid silicones, also: 2K-LSR (LSR = liquid silicone rubber). They crosslink at high temperatures.

- The silicone rubbers which cross-link at room temperature (RTV). Their short form is also 1K-RTV or 2K-RTV, depending on the number of components.

- Especially addition-curing silicones (A silicones) are in particular suitable for medical and biotechnological applications. They permit precise shaping.

- If the catalyst of the cross-linking reaction is activated through UV light, we talk about UV-curing silicone rubbers.

We help you to find the right type of silicone from this large variety that fits best to your application. We would be pleased to inform you about the properties of our certified materials. The best possible realization of your silicone products is tested at our laboratory unit.

Alternatively we check and use your preferred fluid silicones, regardless of the manufacturer. By testing the material in advance at our laboratory unit, we are able to precisely determine the ways of product realization.

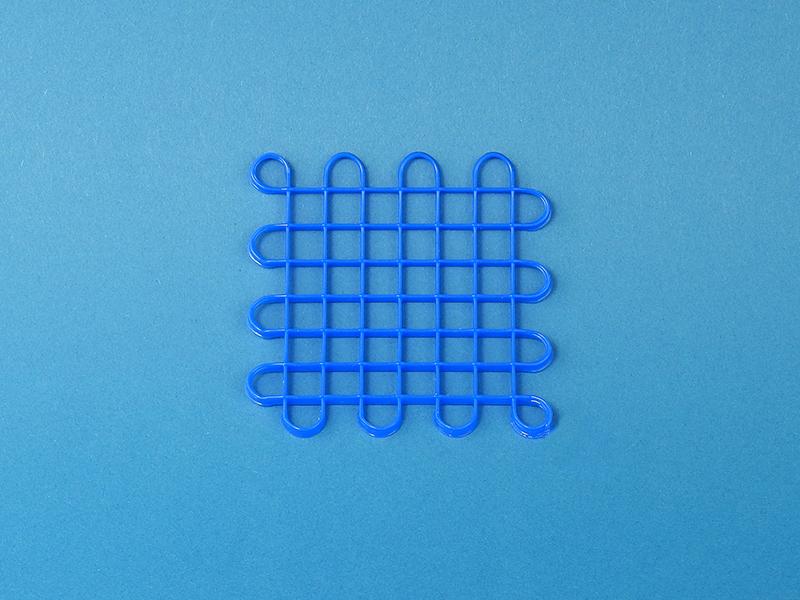

Coarse, colored grid – plotted in blue

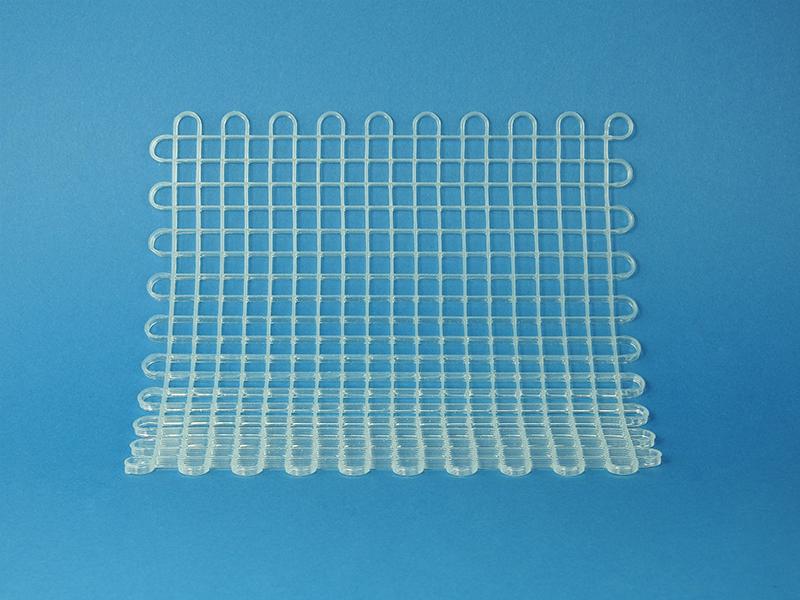

6-layer coarse silicone grid- suitable as a laboratory mat

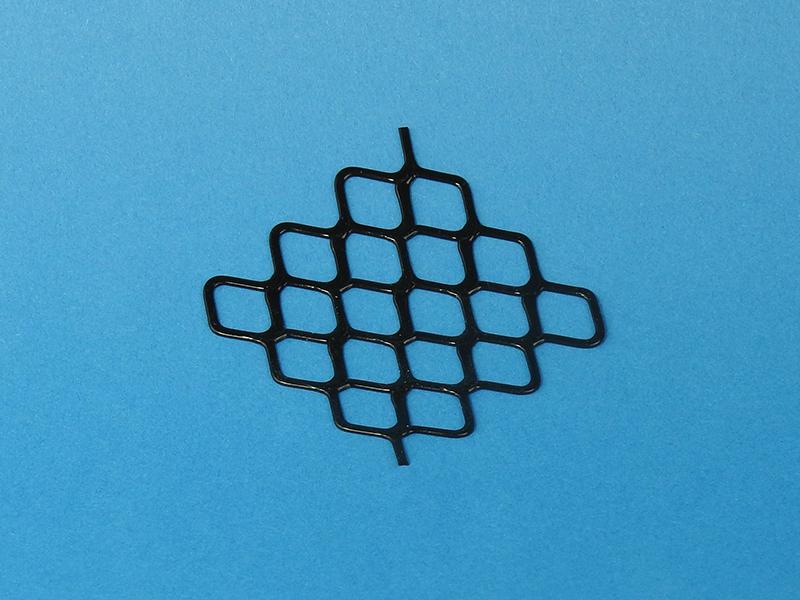

Free-formed and flexible strip conductors – large-meshed black grid made of conductive silicone (version 1)

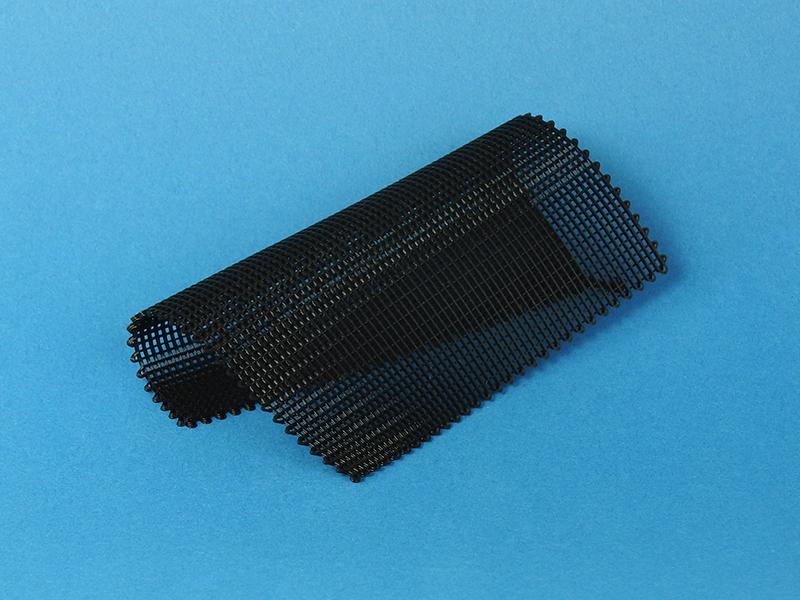

Free-formed and flexible strip conductors – small-meshed black grid made of conductive silicone (version 2)

Biocompatible silicones

Certified silicones guarantee compatibility

The biocompatible silicones processed at KET are all tested and certified in accordance with the directives of USP Class VI and ISO 10993. Series production is run by trained and qualified staff under clean-room conditions. We attach great importance to high processing standards.

Wether in moist wound care or in cell cultivation in the bio-medical sector, our customers benefit from our know-how and our patented technology every day.